MT Frequently Asked Questions

Overview

This article is intended to provide a summary of the frequently asked questions on MT sensors.

Licensing

How does licensing work?

MT sensors require a dashboard license to operate, however, the licenses are not hardware-SKU specific.

How does the free licensing work?

Similar to the free MV sense licenses, Meraki provides five free licenses for MT sensors to all new and existing organizations, and these licenses do not expire. Note that these licenses cannot be transferred to another organization in either co-termination or Per-Device Licensing model.

Free licensing for MT is not available in Subscription model.

2 Free MT Licenses with MR Advance License

What is the offering?

All new and existing organizations with MR Advanced Licenses will now include 2 Free MT Licenses for every MR Advance license.

Note that this offering is in addition to the already existing 5 Free MT licenses for every organization.

For example - If a license with 20x MR-ADV SKU is claimed in an organization, 40x MT-FREE-LIC are also added.

Is this a limited time offer?

No. This is not a limited time promotion. The 2 free MT licenses are effective as long the MR Advance License is applied.

Which licensing model does this apply to?

Currently this only applies to Co-term organizations.

On Subscriptions, we offer offer 1 free LIC-MT-E license with every LIC-MR-A purchased (not yet available for LIC-CW-A or EAs). Learn more here.

PDL is not eligible for this program.

What features does it include?

Free MT licenses are exactly the same as a regular MT license. All MT features are included.

Does it affect my co-term date?

No.

Free MT License tier doesn’t have any time period associated with it. The licenses are tied to the MR Advance licenses. As long as the MR Advance licenses are active in the organization, 2x Free MT licenses will remain active in that organization.

Can I add more MT licenses?

Yes. A regular MT license can be claimed on top of the free licenses. Note that any regular MT licenses(MT-LIC-XY) will have a term associated with it and will account into the co-term date as any other license.

Can the free MT licenses be moved to a different organization?

No.

As mentioned above, the MT licenses are tied to MR Advance licenses. If the MR license is moved to another organization, the MT licenses will follow. However, the Free MT licenses cannot be moved by themselves.

What happens if MR Enterprise License is upgraded?

If an MR-Upgrade license is added to an organization, 2x Free MT licenses will also be added to the organization for every MR advance license.

What happens if MR Advance License is downgraded?

The Free MT Licenses are only valid as long as MR Advance License is active on the organization. If that license is removed or no longer active, the MT license will be removed.

Note that the 5 Free MT Licenses will remain unaffected by the downgrade.

How are existing MR Advance users notified of the promotion?

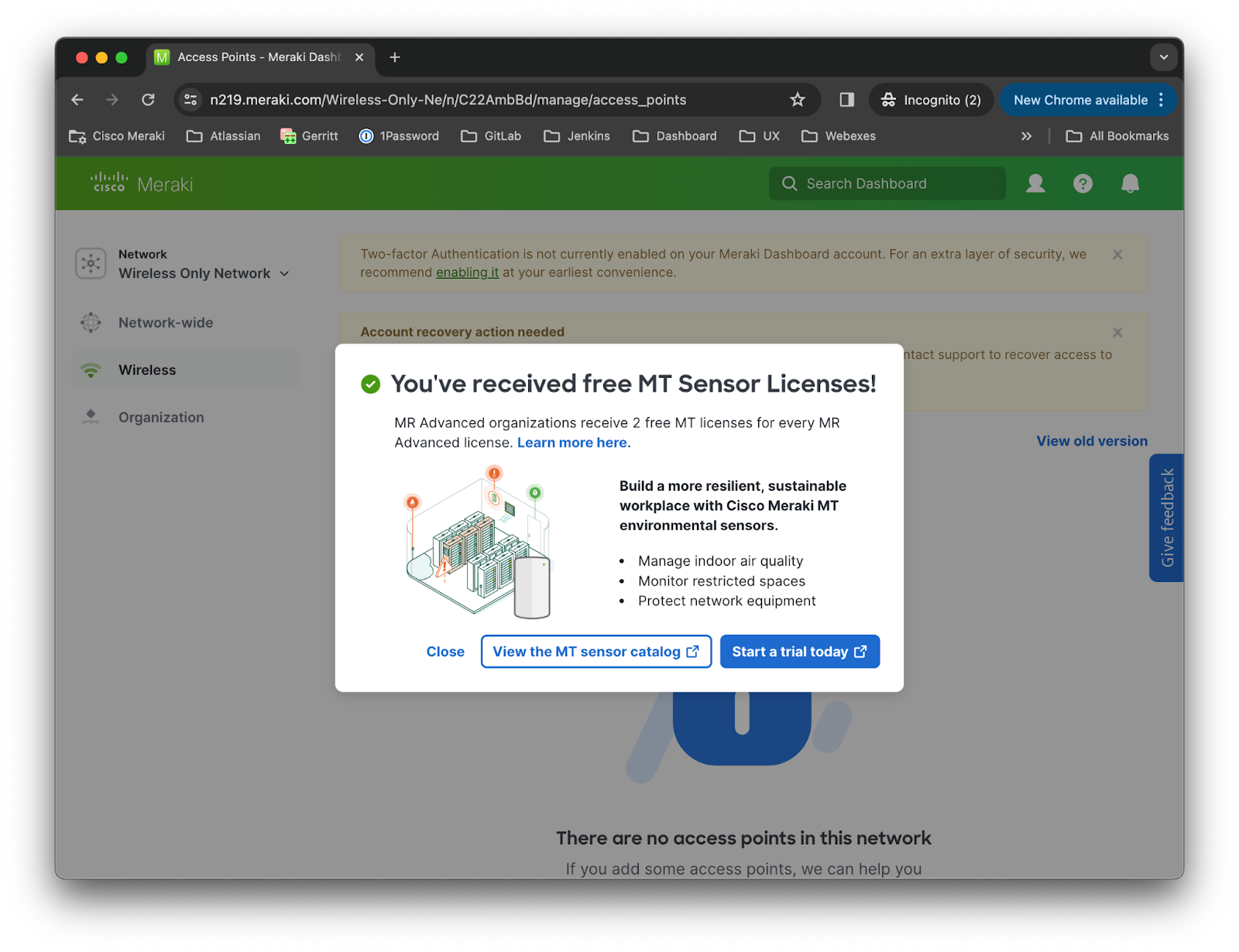

Existing organizations with an active MR Advance license will be shown the following popup on the first time navigating to Wireless>List page:

This popup is only visible to organization administrator and is user dismissible.

Connectivity

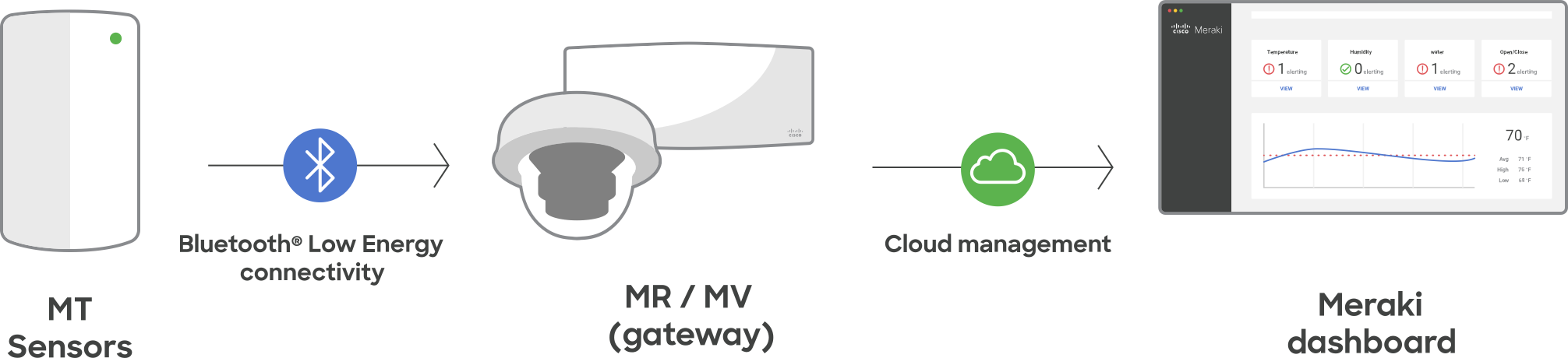

How do MT sensors communicate with the Meraki dashboard?

MT sensors use Bluetooth® Low Energy to communicate with Meraki IoT gateways.

A full list of supported gateway models and firmware is below; if your model is not listed here, then it's not supported to be used with MT sensors.

Refer to the Product Firmware Version Restrictions document for specific model minimum runnable firmware versions.

General FAQs

Do MT sensors support Wi-Fi 5 (802.11ac Wave 2) APs as gateway?

Yes. The MT functionality was ported to be supported on Wi-Fi 5 Wave 2 APs. A firmware update expanded the functionality of the existing BLE radio to allow MT devices to use them as gateways. The minimum firmware requirement for MT support on Wi-Fi 5 APs is MR 28.6+. Please refer to the list of compatible gateways for accurate and up-to-date information.

How does the sensor connect to its gateway?

As long as the minimum firmware requirements (see above question) are met as per the MT Installation Guides and the sensor is within range of the gateway, it will automatically connect to any compatible gateway that picks up the Bluetooth Low Energy advertisement of the sensor.

MT sensors cannot be assigned to a specific gateway. When a sensor wakes up, it will connect to any gateway in range, which is in the same Dashboard network.

What happens when MTs can’t communicate with the Meraki dashboard?

MT sensors have enough onboard storage to retain approximately five days of data, except for MT14, MT15 and MT40 which will retain measurements for approximately 12 hours. Upon reconnecting to the Meraki dashboard, all data points will be uploaded.

What is a good signal strength for MT devices?

The RSSI LED indicator for MT devices is as follows:

> -65 dBm - Green

< -66 dBm and > -84dBm - Yellow

< -85 dBm - Red (Connection is rejected)

Sampling rate and frequency of connections

In order to conserve battery life, MT sensors are in sleep mode the majority of the time. They wake up at a set regular interval to connect and report data to the gateway, which in turn uploads it to the Meraki cloud. Below is the sampling rate and connections per device type:

| MT | Data Sampling & Connection Interval |

|---|---|

| MT10 | Data sampling: 2 minutes Connection interval: 20 minutes |

| MT11 (w/temperature probes) |

Data sampling: 2 minutes |

| MT12 | Data sampling: event driven Connection interval: 20 minutes |

| MT14 |

Data sampling*: Connection interval: 20 minutes |

| MT15 |

Data sampling*: Connection interval: 20 minutes |

| MT20 | Data sampling: event driven Connection interval: 20 minutes |

| MT30 | Data sampling: event driven Connection interval: 20 minutes |

| MT40 | Data Sampling: 15 seconds Connection Interval: 20 minutes or On Demand from UI |

Data sampling rate is changed when the MT14 is configured to run in High Sampling Mode.

All sensors will wake up immediately if a configured threshold has been violated. In a binary sensor like MT12 or MT20, the sensor will wake up if any event occurs.

Deployment

What firmware on MV and MR is required for MT to work?

How far can the MTs be placed from the MR/MV gateway?

MT Sensors use Bluetooth Low Energy 4.2 to communicate with the gateway. Since Bluetooth Low Energy operates between 2.402 and 2.480 GHz, the range depends on the same principles as 2.4 GHz Wi-Fi.

How many sensors can be used per gateway?

It is recommended to have a maximum of 32 sensors per gateway to ensure connection quality.

Minimum firmware requirement for a gateway to support 32 sensors:

MR - 28.5+

MV - 4.14+

Any firmware older than above only supports eight sensors per gateway.

Are MTs rated for outdoor use?

No, MT devices are designed for indoor use only. The MT12 is IPX5-rated (can resist a sustained, low-pressure water jet spray) and has a rubber liner to separate the power/battery compartment from being splashed or exposed to water. The sensors should still not be submerged in water, as the rating states.

What are the supported temperature and humidity ranges for the MT10?

The temperature sensor supports 0°C - 55°C / 32°F - 131°F (accuracy: +/- 0.3°C) using the included AA batteries. The humidity sensor ranges from 0-95%. However, it is not an outdoor (IP67) or harsh-environment-rated product.

MT11 temperature probes supported range

Below are the specified temperature ranges of the MT11 temperature probes. Note that the operating temperature of the MT11 body is 0°C - 55°C / 32°F - 131°F.

Bare metal probe MA-CBL-TEMP-ME-1)

Range: -40°C - 55°C

Accuracy:

-10°C - 55°C = +/- 0.5°C

-30°C - 55°C = +/- 1°C

-40°C - 55°C = +/- 2°C

Glycol probe (MA-CBL-TEMP-GL-1)

Range: -40°C - 55°C

Accuracy:

-10°C - 55°C = +/- 0.5°C

-30°C - 55°C = +/- 1°C

-40°C - 55°C = +/- 2°C

Can MT10 be used to monitor temperature and humidity inside of a freezer?

The sensors are not IP rated and should not be installed inside of freezers.

Can the MT11 temperature probes be used to monitor temperature of fluids?

No. MT11 temperature probes are not rated to monitor temperature of any fluids, including water.

Do the MT10/MT11 temperature sensors need to be calibrated?

No. The MT10 temperature sensor and the MT11 temperature probes use a digital sensor that comes pre-calibrated during the manufacturing process. This means no calibration is required during the product life cycle.

Does the MT14 Air Quality Sensor need to be calibrated or cleaned?

No. The MT14 does not require any external calibration or cleaning. Some of the internal components are designed to be self-calibrated and also have cleaning routines. Below is the breakdown on a metric basis:

1. Temperature/Humidity - Same component used in MT10 which doesn't require any calibration.

2. Total Volatile Organic Compound (TVOC) - This component has a self-calibrating mechanism which "learns" the environment it is installed in. Upon the first boot (immediately after unboxing the sensor for the first time), the refinement period lasts up to 48 hours. This refinement period is run for every subsequent reboot, though it lasts only a few hours.

During the TVOC Refinement Period, the readings may not be accurate as the sensor is still calibrating the baseline metrics.

3. PM2.5 - The PM2.5 component doesn't require any calibration. However, it does have a cleaning mechanism which increases the fan at the bottom of the device to eject any dust that has accumulated in the sensor. The routine runs every 72 hours.

For best results, it is highly recommended to install the device with vents facing down to assist with both calibration and cleaning routines.

What part of the MT12 is capable of detecting water?

- MA-CBL-LEAK-1: The full length of the cable can detect water as little as 3 mL. The cable is 8 ft long, and can be extended to 16 ft with an optional second cable attachment.

- MA-CBL-LEAK-2: The coiled cable running through the back of the cradle is water sensitive and can detect water as little as 3 mL.

The leak detection cable(MA-CBL-LEAK-1) and cradle(MA-CBL-LEAK-2) is sold separately.

What are the power requirements for MT sensors?

Here is a list of all the MT sensors and their supported power requirements.

| Model | # of Batteries | Expected Battery Life | External Power |

|---|---|---|---|

| MT10 | 2 | 5 Years | Yes |

| MT11 | 2 (pre-installed) | 5 Years | Yes |

| MT12 | 2 | 5 Years | No |

| MT14 | 4 | 2 Years | Yes (required for PM2.5 readings and High Sampling Mode) |

| MT20 | 1 | up to 5 Years* | No |

| MT30 | 1 | up to 5 Years* | Yes |

NOTE:

1. MT20 and MT30 Battery life is dependent on the usage of the sensors. The expected battery life is based on up to 100 triggers per day.

2. The battery curve of MT sensors is based on typical usage of an Alkaline-based battery which is included in the box. Other types of battery cell(such as Lithium) may yield different results.

3. MT 2.0 firmware updates the battery curve to be more optimized and accurate for MT20 and MT30. The battery reported will be up to 20% lower than previous firmware but the battery life remains unchanged.

MT40 Smart Power Controller

What are the power monitoring capabilities?

|

Power Monitoring |

|

|---|---|

|

RMS Voltage |

Range: up to 250 V Accuracy: +/- 1% V |

|

RMS Current |

Range: 100-120VAC, 50-60Hz, 12A max 200-240VAC, 50-60Hz, 10A max Accuracy: +/- 1% A |

|

Real Power |

Range: up to 2400 W Accuracy: +/- 1% W |

|

Apparent Power |

Range: 0 - 250V Accuracy: +/- 1% V |

|

Power Factor |

Range: 0 - 100% Accuracy: +/- 1% |

|

Energy |

Range: up to 144 kWh Accuracy: +/- 1% |

What is the maximum current MT40 supports?

As mentioned above, MT40 can support a sustained load of 12A under ambient conditions. This value is de-rated from 15A and above. MT40 can record transient spikes above 12A but is not recommended for sustained load.

Does MT40 have surge protection?

No. MT40 is strictly a power monitor and controller. This unit is not intended to be used as a surge protector. Using a surge protector or a power conditioner upstream of the MT40 is recommended.

What cables are needed for MT40?

MT40 is designed to be a universal power monitor and controller. With that in mind,

Input - IEC C14

Output - IEC C13

This means that a user can order a region specific input cable as well as output cable.

Supported Accessories -

MA-PWR-CORD-XX (region specific input cable)

MA-PWR-C14-C15-1 (output cable for a device with C14/15 receptacle)

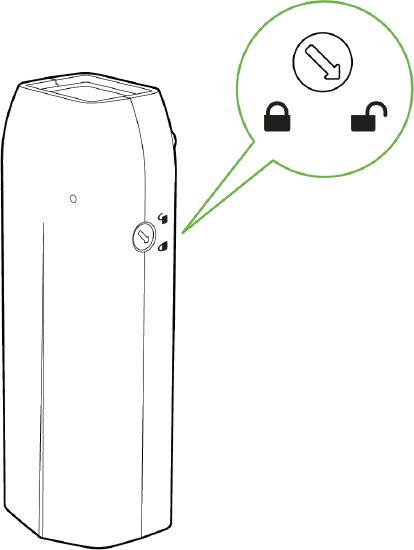

What does the physical lockout switch do?

The physical lockout switch is used to enable/disable remote access for controlling downstream power. For certain use cases where a user doesn't want to control the downstream power, the feature can be physically disabled by pointing the arrow to the "locked" icon.

A flat head screwdriver should be used to toggle the switch between states.

How much power does the MT40 itself draw?

Maximum expected power usage is 2W, but typical usage is between 1.2W to 1.6W when downstream power is enabled. With downstream power disabled, power usage is much lower. Note that the device power usage is not reported on the Dashboard.

Alerting and Monitoring

What kinds of alerting does MT sensors support?

MT sensors support email, SMS, and Webhook alerts out of the box, without any need for Twilio (or similar integrations). MT sensors also support push updates from the Meraki app. Please refer to the Sensor Alert Profiles article in order to set up alerting.

Do MT sensors support APIs?

Yes. Detailed documentation regarding APIs can be found by visiting Help>API docs on the Meraki dashboard.